The Future of ERP in Industry 4.0

- Industry 4.0

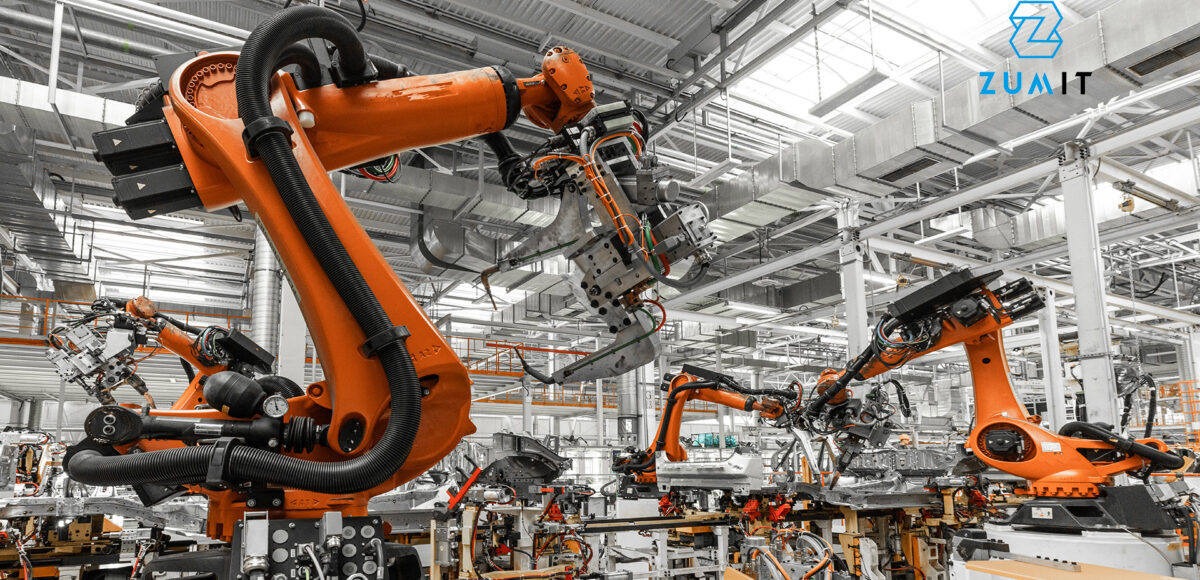

Industry 4.0 was first introduced at the Hannover Fair in 2011 and officially announced in 2013 as a strategic initiative by Germany to lead the transformation of the manufacturing sector. Often referred to as the Fourth Industrial Revolution, Industry 4.0 marks the integration of advanced automation technologies into industrial processes.

At its core, Industry 4.0 is powered by key technologies such as cyber-physical systems (CPS), the Internet of Things (IoT), and cloud computing. This evolution represents a shift from traditional embedded systems to interconnected, intelligent networks that merge the virtual and physical worlds. Through IoT and CPS, machines and systems communicate seamlessly, enabling real-time data exchange and decision-making.

One of the most significant developments in Industry 4.0 is the rise of smart factories, designed to manage complex production environments through advanced digital integration. This transformation relies heavily on Information and Communication Technologies (ICT), which provide the foundation for industrial innovation. With embedded systems, IoT, CPS, and industrial integration playing crucial roles, Industry 4.0 is reshaping manufacturing by enhancing efficiency, flexibility, and connectivity in an increasingly digitalized world.

- The Evolution from Industry 1.0 to Industry 4.0

To understand the progression of industrial development, it is essential to trace the transformation from Industry 1.0 to Industry 4.0. This evolution highlights the increasing role of industrial integration and information technologies, particularly in the emerging era of IoT and CPS.

The First Industrial Revolution, which emerged in the late 18th and early 19th centuries, was characterized by the introduction of mechanical manufacturing powered by water and steam. The Second Industrial Revolution, beginning in the late 19th century, marked the shift to mass production driven by electrical energy. The Third Industrial Revolution, which started in the mid-20th century, introduced automation and microelectronics into manufacturing, significantly advancing production processes through innovations such as CNC systems, industrial robots, and computer-integrated manufacturing (CIM).

Now, the manufacturing sector is undergoing the Fourth Industrial Revolution, or Industry 4.0. This new phase is defined by the integration of cyber-physical systems (CPS), the Internet of Things (IoT), and cloud computing. While the Third Industrial Revolution focused on automating individual machines and processes, Industry 4.0 aims for complete digital transformation, enabling seamless connectivity across entire industrial ecosystems. The implementation of smart devices, advanced data analytics, and business process management (BPM) further enhances this shift, creating an intelligent, fully integrated, and highly efficient industrial landscape.

- ERP and Its Role in Industry 4.0

Enterprise Resource Planning (ERP) is a software system that integrates core business processes, such as finance, supply chain management, production, human resources, and customer relationship management, into a unified platform. ERP enables organizations to streamline operations, improve decision-making, and enhance efficiency by providing real-time data access and process automation.

In the context of Industry 4.0, ERP systems play a crucial role by acting as the digital backbone of smart factories and connected enterprises. The seamless integration of ERP with Industry 4.0 technologies, such as IoT, CPS, and cloud computing, enables manufacturers to achieve end-to-end visibility, optimize resource allocation, and enhance production planning.

The relationship between ERP and Industry 4.0 can be seen in several key areas:

- Data Integration and Connectivity: ERP systems consolidate data from various sources, including IoT-enabled machines, sensors, and production lines, to provide a unified view of operations.

- Automation and Smart Decision-Making: By leveraging AI and advanced analytics, ERP systems help businesses automate workflows and make data-driven decisions in real-time.

- Supply Chain Optimization: ERP facilitates supply chain synchronization, predictive maintenance, and demand forecasting, reducing delays and inefficiencies.

- Scalability and Flexibility: Cloud-based ERP solutions offer scalability and remote accessibility, allowing companies to adapt to changing market demands and production needs.

- Enhanced Customer Experience: With better data management and process automation, companies can provide improved services, reduce lead times, and enhance customer satisfaction.

By integrating ERP with Industry 4.0 technologies, businesses can drive digital transformation, improve operational efficiency, and stay competitive in an increasingly connected industrial landscape.

- Future Trends of ERP and Potential Disruptive Technologies

The evolution of ERP systems is being shaped by emerging technologies that align with the advancements of Industry 4.0. The following table highlights key trends that are expected to redefine ERP capabilities, enhancing efficiency, intelligence, and adaptability. Each of these technologies plays a crucial role in ensuring ERP systems remain competitive in an increasingly digital and data-driven environment. Future Trends in ERP

| Future Trend | Description |

| Cloud-based ERP | Enhances accessibility, scalability, and cost-effectiveness by enabling ERP solutions to operate on cloud platforms. |

| Mobile ERP | Provides real-time access to ERP functionalities through mobile devices, improving flexibility and remote management. |

| AI-Integrated ERP | Incorporates artificial intelligence to automate processes, enhance decision-making, and optimize operations. |

| Business Intelligence (BI) in ERP | Enables data-driven insights through analytics and reporting, facilitating informed decision-making. |

| Internet of Things (IoT) in ERP | Connects physical devices to ERP systems, improving real-time monitoring and data collection. |

| Blockchain Technology in ERP | Enhances security, transparency, and traceability in transactions and supply chain processes. |

| Big Data in ERP | Leverages large-scale data analysis to optimize processes, predict trends, and improve operational efficiency. |

| Omnichannel ERP | Integrates multiple sales and communication channels to provide a seamless customer experience. |

- Transition to Cloud-Based ERP

Over the past few decades, cloud computing has made remarkable strides, emerging as a transformative force for ERP systems. Unlike traditional on-premises solutions, cloud ERP enables data storage and processing on remote servers, offering greater flexibility, accessibility, and customization. Organizations can access their ERP systems anytime, from anywhere, ensuring seamless operations across multiple locations.

Cloud ERP provides several advantages over conventional ERP systems, including cost reductions of approximately 15%, faster implementation (50%-70% improvement), and enhanced agility. Many organizations have already transitioned to cloud ERP, with adoption rates continuing to rise. Between 2016 and 2017, global market share for cloud ERP saw an increase of 11%-27%, while IT budgets allocated to cloud ERP grew by 15%-25%. It is projected that more than 70% of organizations will migrate their IT infrastructure to cloud-based platforms in the coming years.

Several factors are driving this shift. Large enterprises, particularly those preparing for Initial Public Offerings (IPOs), view cloud ERP as a prerequisite due to its scalability and efficiency. Additionally, cloud software has gained a strong reputation for its market adaptability, making it an attractive option for businesses of all sizes. Small and medium-sized enterprises (SMEs) are also expected to benefit significantly, as cloud ERP lowers entry barriers and enhances competitiveness.

The adoption of new technology remains a critical success factor for businesses. Cloud ERP simplifies software management, enhances performance, reduces costs, and minimizes maintenance efforts. Moreover, it serves as an ideal platform for integrating future IT innovations into ERP ecosystems. While factors such as data security, cost-effectiveness, and executive support influence cloud ERP adoption, research suggests that manufacturing companies exhibit a stronger inclination toward cloud ERP compared to service-oriented businesses.

- Mobile ERP

The rapid growth of mobile devices and wireless internet has enabled the adoption of ERP services on smartphones and tablets (iOS and Android) with active internet connections. While the concept of Mobile ERP began emerging in the early 2000s, it has gained significant traction in recent years as mobile devices have become integral to daily life. Mobile ERP leverages cloud-based systems for central data management, allowing for enhanced accessibility and real-time updates. Key benefits of Mobile ERP include anytime, anywhere access to data, customizable options, and quicker updates. Despite its potential, there are challenges, particularly in terms of user interface design and usability. Complex and cluttered interfaces can hinder the effective use of mobile ERP systems. As technology continues to evolve, improvements in these areas will likely enhance user experience and drive further adoption of Mobile ERP solutions.

- Artificial Intelligence and Large Language Models

Artificial Intelligence (AI) is an evolving field that plays a pivotal role in transforming various industries, particularly through its integration with machine learning techniques. AI systems are designed to generate new knowledge, adapt to changing environments, process incomplete or faulty data, and make informed decisions. These intelligent systems monitor key variables, identify potential risks, predict future outcomes, and suggest action plans to optimize processes.

One of the most significant advancements within AI is the development of Large Language Models (LLMs), which have the ability to understand and generate human-like text based on vast amounts of data. LLMs, powered by sophisticated algorithms, can process and interpret complex language patterns, enabling them to perform a variety of tasks such as content generation, sentiment analysis, translation, and question answering. These models continue to evolve, leveraging large datasets and advanced neural network architectures to enhance their capabilities.

LLMs, like OpenAI’s GPT, are capable of not only processing raw data but also understanding context, handling ambiguity, and generating coherent and relevant responses. They can be integrated into various applications such as customer support systems, content creation, and automated decision-making, providing organizations with powerful tools to streamline operations and improve efficiency.

However, while LLMs offer numerous benefits, there are challenges related to their implementation, including ensuring the quality and accuracy of the data used for training, addressing biases in the model, and managing the computational resources required for large-scale deployment. Despite these challenges, the potential for AI and LLMs to revolutionize industries is immense, making them essential components in the future of automation and intelligent decision-making.

- Business Intelligence (BI)

Business Intelligence (BI) plays a vital role in business analytics and decision-making within organizations. It refers to computerized analytical tools that transform data into actionable information and knowledge, helping organizations make informed business decisions. The integration of BI into Enterprise Resource Planning (ERP) systems can offer several advantages, including empowered decision-making, enhanced customer interactions, greater flexibility in generating information, improved IT infrastructure, seamless integration of information across the organization, and more efficient information flow across departments.

Despite these benefits, many organizations have yet to fully experience the potential of BI in their production planning. When integrated into ERP, BI can provide advanced business data analytics, such as data mining, text mining, predictive analytics, statistical analysis, and macro analysis. This capability is instrumental in supporting a broad range of business decisions, from operational to strategic, and includes both internal and external business data.

The successful adoption of BI in ERP systems depends on several factors, including technological aspects (system, service, and information quality), organizational considerations (change management, effective communication, and training), and environmental influences (clear vision and planning, competitive pressure, policy, and government involvement). However, BI systems do have some limitations, such as their inability to quickly adapt to rapid market changes or prevent unforeseen events. Despite these challenges, BI continues to be a valuable tool for improving business decision-making.

- Internet of Things (IoT) and Industrial Internet of Things (IIoT)

The Internet of Things (IoT) refers to a network of physical devices embedded with sensors or software that are connected via wired or wireless internet connections. These devices monitor their surroundings and automatically respond to changes within their ecosystem. The growing adoption of IoT technologies across various industries is driving the development of Industrial Internet of Things (IIoT).

IIoT, as defined by industry experts, is a network of smart, highly connected industrial components designed to optimize production rates, reduce operational costs, and enhance industrial process management. This is achieved through real-time monitoring, efficient control, and improved asset management.

IoT and the large data flows it generates are transforming the ERP landscape by enabling new opportunities for operational efficiency and workflow automation. For example, Radio Frequency Identification (RFID) tags have proven valuable in inventory management, with companies like Walmart reducing their inventory by 70% through RFID adoption. As a result, RFID technology is expected to play a key role in future ERP systems, especially for real-time tracking of goods in industries.

The ability of IoT devices to collect vast amounts of data from multiple sources, combined with their connectivity to cloud systems, allows for seamless integration with ERP systems. However, there are several challenges in integrating IoT with ERP, such as device heterogeneity, functionality differences, managing big data, and addressing security concerns. Despite these challenges, the potential of IoT and IIoT to improve business processes and decision-making is substantial.

Blockchain Technology

Blockchain is a decentralized, distributed, and immutable database system that maintains a secure and irreversible ledger. It enables transactions to be verified and exchanged without the need for a central authority. The blockchain consists of a series of blocks, such as the parent block, uncle block, and genesis block, each containing transaction data similar to a traditional public ledger. Each block references the previous one through a hash value, creating a continuous chain.

In manufacturing, blockchain technology can be integrated with various innovative technologies, such as 3D printing, CAD/CAM, and quality monitoring systems, within ERP systems. Additionally, blockchain can extend the capabilities of ERP in design and procurement processes. For example, Renault, the French automaker, utilized a Microsoft Azure-based blockchain ERP to manage car ownership, track products, and streamline new design processes. Blockchain’s ability to preserve product information throughout the entire procurement lifecycle offers customers enhanced track-and-trace capabilities, better visibility, improved control, reduced risk, and greater regulatory compliance.

Integrating blockchain into ERP systems can enable businesses to access up-to-date information and efficiently manage the sharing of data across networks. Despite its many advantages, blockchain faces several challenges for future implementation. Key concerns include scalability, as seen in Bitcoin’s transaction limit of 7 transactions per second, which could lead to large blockchain sizes. Additionally, issues such as privacy concerns, hidden mined blocks, and high energy consumption need to be addressed for future advancements in blockchain technology.

- Big Data

Big Data refers to the vast volumes of data generated through technological advancements. With the rise of high-speed internet, social media, computing systems, and Information Technology (IT), the amount of data produced daily has grown exponentially, often reaching over 2.5 quintillion bytes. This massive influx of data is commonly known as Big Data.

Big Data technology encompasses a complex system involving data collection, processing, distributed storage, parallel computing, and data visualization. These technologies are widely utilized in enterprise management processes to enhance decision-making and operations. The integration of Big Data into Enterprise Resource Planning (ERP) systems can enable organizations to adopt better “best practices,” resulting in faster, higher-quality implementations.

In 2014, one of the leading ERP vendors, SAP, began collaborating with Databricks to develop a data-analytical ERP system. By 2017, they launched the first Big Data-based ERP called “Vora.” This system allowed ERP to generate business transactional data, while Big Data systems could collect data from various sources such as social media, the Internet of Things (IoT), and mobile devices. These diverse datasets were then integrated into an analytic system, marking a significant advancement in the evolution of Big Data-ERP systems.

The Vora system opened new possibilities for research into integrating data-driven technologies into future ERP systems. However, significant challenges remain in the integration of Big Data with ERP. These challenges include the complexity of data, arising from varying data types, structures, interrelationships, and computational demands. Given that Big Data comes from multiple sources in enormous volumes, it requires more powerful computational systems to be effectively incorporated into future ERP systems. Furthermore, issues such as data heterogeneity, incompleteness, scalability, and privacy concerns need to be addressed as Big Data-ERP systems continue to evolve.

- Omnichannel Strategy

Technological advancements have created a wide array of communication channels for businesses to engage with consumers, significantly impacting business models and customer interactions. Omnichannel refers to the integration of multiple channels, providing a seamless and unified customer experience. While multichannel involves using several distinct channels, cross-channel refers to partial integration of those channels. Omnichannel, on the other hand, fully integrates these channels to ensure a consistent experience for the customer.

Omnichannel strategies encompass various aspects of a retailer’s operations, including shipping, logistics, sales tools, promotions, and performance metrics. This approach allows customers to place orders online and pick them up in physical stores, commonly known as the “click and collect” model. As a result, businesses must ensure that products are available across various channels, regardless of how, where, or when the orders are placed.

For businesses looking to integrate different channels and provide customers with consistent access to information, ERP systems are an essential solution. A strong correlation exists between the ability to display channel information and the integration of online and offline inventory within a single warehouse. For example, RFID tags have been implemented in fashion retail supply chains to streamline the flow of information across various channels, such as warehouses and inventories, supporting models like “see-now-buy-now.” In this scenario, ERP systems serve as the central hub connecting customers with the necessary information channels, ensuring smooth operations and improved customer satisfaction.

- Conclusion

The future of ERP in Industry 4.0 is driven by smart technologies that enhance automation, decision-making, and operational efficiency. Businesses that embrace these innovations will gain a competitive advantage, optimize their processes, and improve overall productivity. As ERP continues to evolve, organizations must strategically plan their digital transformation journey to maximize the benefits of Industry 4.0.

Leave a Comment